CUSTOM TIMBER DOOR MANUFACTURING

An immensely crucial part of any fitout, timber doors are a perfect way to craft an entry from a necessity into an eye-catching marvel. Now boasting increased capacity to manufacture doors in house, we’ve opened a world of opportunity. From paint-grade, to acoustic, secure and veneer and laminate doors, there’s a door type for all spaces!

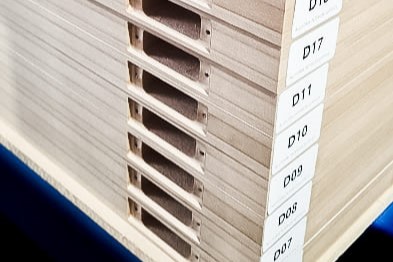

STEP ONE: SELECT INTERNAL CORE

Based on the environment the door will be in, a range of internal cores are available:

- Semi-solid: Lightweight yet substantial, perfect for interior doors that won’t be slammed too often.

- Solid MDF: The classic choice for a sturdy interior door that needs a little extra sound absorption.

- Particleboard: Solid-core strength with a lightweight feel. Ideal for high-traffic areas, especially external.

- Blockboard: The ultimate in stability, great for external use and high-security areas.

STEP TWO: SELECT FACE FINISH

This is the fun part! A massive range of face finishes are available, from pre-primed paint-ready to eye-catching veneers and laminates.

- Pre-primed MDF: Paint prep done and ready for the finishing touch.

- Duracote XP: Super tough and ready to paint, ideal for busy areas. Usually used with block or particleboard cores.

- Veneers and laminates: From warm oak to sleek ebony, add a touch of natural elegance to any space with veneer and laminate doors. A range of brands available, including Polytec, Briggs, Laminex and George Fethers.

STEP THREE: LET US DO THE DIRTY WORK!

Ditch the jigsaw and leave the precision machinings to us. We can handle everything you need, from mortice and latch preparation to drop seals and glazing – even in veneer and laminate doors. Just tell us what you want, and we’ll make it happen.

Take CASA, for example, where airplane-style vision panels stole the show, in both veneer doors and paint-grade doors.

Or Ashurst law offices, where laminate doors were fully glazed and machined for hardware.

And the DHA offices in Gungahlin, where again, machining was required for veneer doors.

AVAILABLE MACHININGS

A range of hardware machinings available:

PRE-MORTICE

Ready for immediate mortice lock installation.

SEAL GROOVE

Recessed drop seal groove to base of door. Available to suit a range of Raven and Kilargo seals.

REBATE

13mm rebate on long edge of door, used for double timber door sets.

LATCH

Alternative to mortice, used for free passage doors.

PANEL CUT-OUT

Cut-out for Alu-vent or Alu-lite vision panel. Also available with beads for timber glazed vision panel.

ROLLER BOLT

Cut-out to facilitate immediate installation of roller bolts.

GLAZING

Timber bead vision panels or full glazed timber doors. Regular and non-regular shapes available.

EDGESTRIPS

Neat, continuous edge for veneer and laminate doors.

FLUSH BOLT

Automatic flush bolt prep to edge of door.

TRANSOM CLOSER

Concealed door closer cut-out to top or bottom of door.

OTHER HARDWARE

Specialised hardware prep, including pivot closers, guides, rollers and more.

COMBINATIONS

Any combination of machinings.